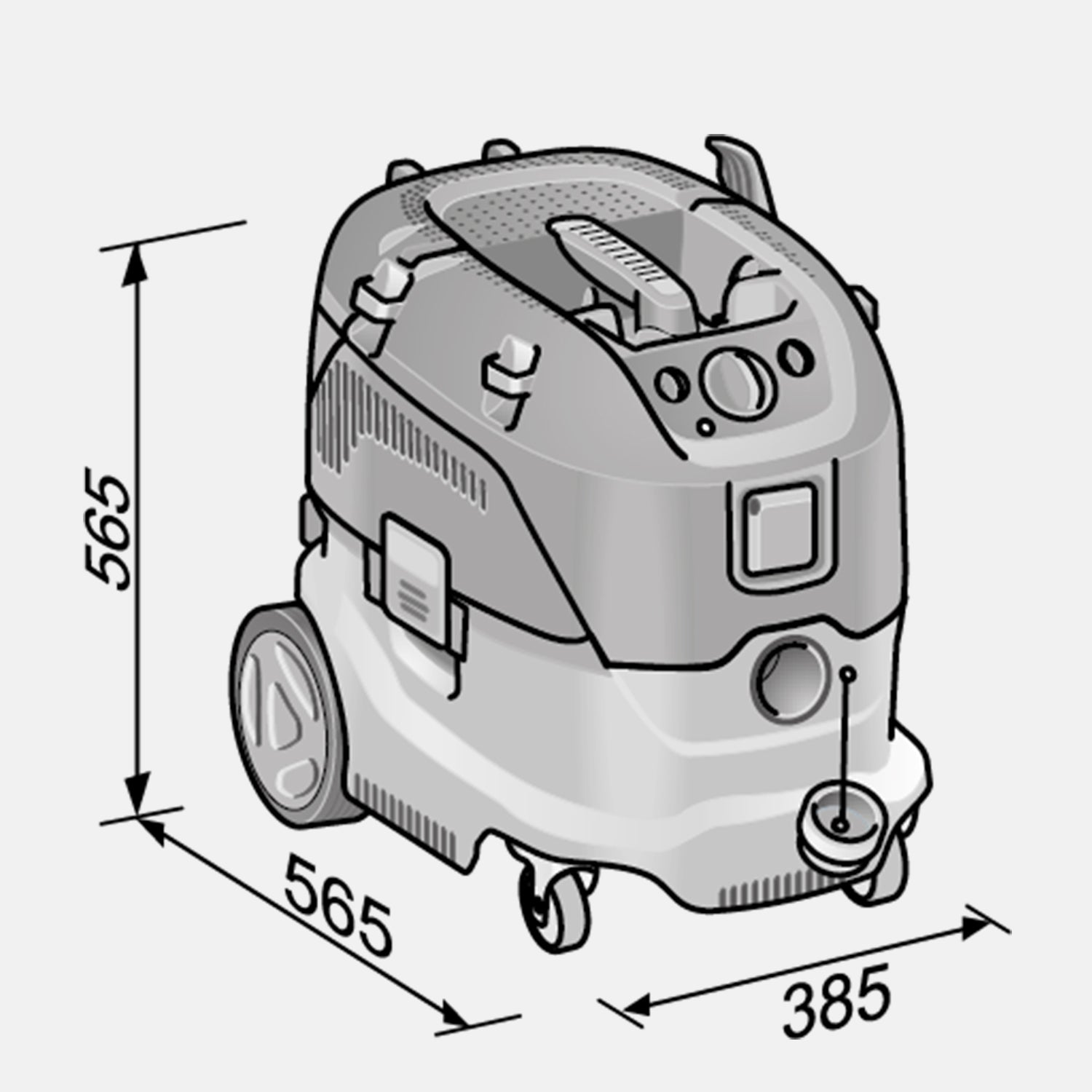

Flex safety vacuum cleaner VCE 33 M AC

Payment and Shipping

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

shipping information

Express shipping . All orders placed before 12pm will be shipped the same day.

For orders under EUR 149, we charge a flat rate of EUR 6.90 per order.

For orders over EUR 149, delivery is free of charge within Germany.

The Flex VCE 33 M AC safety vacuum cleaner offers high suction power and large capacity, ideal for work in the antifouling sector. When removing underwater coatings, fine dust is created that can endanger both health and the environment. The M-class vacuum cleaner is specially designed to safely capture this fine dust.

- Large container capacity : The 30-liter container allows you to work for longer periods without interruption.

- Automatic filter cleaning : Keeps the suction power constantly high, which is particularly advantageous for large areas.

- Certified M-Class filter : Specially designed for dust that is hazardous to health, such as that created when sanding antifouling.

- Mobile and robust : Easy to move and durable for use in demanding conditions.

Why it is important for antifouling work : An M-class vacuum cleaner such as the VCE 33 M AC protects the user from fine dust that is created when sanding antifouling and can be harmful to health. The high filter performance ensures a safe working environment.

| power consumption | 400 W |

|---|---|

| Tension | 230 V |

| frequency | 50/60 Hz |

| grinding disc diameter | 150 mm |

| Hub | 3 mm |

| idle speed | 4000 - 10000 rpm |

| idle stroke rate | 8000 - 20000 rpm |

| connection diameter dust extraction | Ø 27 |

| cable length | 4.0 m |

| Dimensions LxWxH | 230 x 150 x 125 mm |

| Weight | 1.4 kg |

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

FAQs

Use this text to answer questions in as much detail as possible for your customers.

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

FAQ

Visit our guides to learn more.

How many layers do I need?

The number of coats depends on the type of antifouling: self-polishing antifouling requires 2-3 coats for optimal protection, while for hard antifouling 1-2 coats per year are recommended. Biocide-free coatings require at least 2 coats and regular cleaning to maintain the protective effect.

Do I have to remove my old antifouling?

If the existing antifouling is damaged, flaking or incompatible with the new product, it must be removed. A bonding agent can help when changing to compatible antifouling, eg Seajet. Always check the compatibility chart before painting over the old antifouling.

Do I need to use primer?

Primer is important for optimal adhesion of the antifouling. When repainting, apply 3-5 coats of Seajet 117 Epoxy Primer to protect the hull from moisture and osmosis. When switching between two antifouling products, use Seajet 015 Bonding Agent . Check the compatibility table beforehand to make sure the new antifouling is compatible.

Why do you only sell Seajet colors?

Seajet is part of Chugoku Marine Paints Ltd. (CMP) , one of the world's largest manufacturers of coatings for marine and industrial use. CMP has a global network with 105 locations in 35 countries and brings decades of experience in developing high-quality products.

Seajet products are manufactured in a state-of-the-art factory in the Netherlands . This production facility uses the latest technology with renewable energy: 1190 solar cells and geothermal energy ensure sustainable energy supply. Emissions have been reduced by up to 95% , while occupational safety and environmental protection are given the highest priority.

Since the 1990s, Seajet has been providing innovative antifouling coatings, topcoats, primers and paints. The product portfolio combines innovation, quality and environmental responsibility to offer optimal solutions for boat owners worldwide.

Our goal is to make antifouling easier. Instead of offering hundreds of products that all do the same thing, we focus on one suitable product for each application.

How often do I need to renew antifouling?

Self-polishing antifouling should ideally be refreshed with at least one new coat every year . For easy control, we recommend applying each coat in a different color . This way you can immediately see when the antifouling has worn off and where touch-ups are needed. Hard antifouling also requires regular maintenance and should also be renewed annually to ensure optimal protection.